|

I haven't checked into this blog for many months but am amazed that it is still being viewed over 3 years after I finished the boat and last posted an entry. So here's a brief update and links to a few more recent photo's. The boat has still been going well and is still a delight in a breeze. The only issue I've had has been a split joint between the inner side tank panel and floor, due to a weak glue joint exposed when 'kicking' myself back in from the wire. Taping these seams has sorted that. Oh and I had a little crack in the daggerboard so inlaid some carbon tape to address this. Considering that I only really sail the boat in high winds it has seen some abuse but has proved really strong. After 3 winters outside it was looking a little sad so I gave it a new paint and varnish job this year. I wasn't really happy with the original two-tone, so now all in blue with a pin stripe - Looks ok ! A few sailing piccy's (most credits Malcolm Lewis Photography)

3 Comments

Incredible sail today, 2 great races, F5, with awesome long reaches, foot in the footstrap thumping over the waves, managed to sail over a 300, and a few lasers, but lost out on the beats. Great fun, these conditions are exactly what I built her for.

However, I chucked it in blasting about between races and when I righted her, she was full of water again, big time. After wallowing around, rolling in again, I set to reach back home, but she was virtually unsailable, so I hailed a rescue boat, dropped the sail, capsized twice more getting organised and we began a tow before she sank completely !! Took 4 people to get her onto the trolley and up the slip enough to drain. I found there's a long split along the side tank seam where it joins to the floor panel. Gaffer tape tomorrow ! then a big dry out and glass taping required. Ok now I'm finding out what works and what's not strong enough

1. Rudder stock I had to pull hard in at strong wind bear away a couple of weeks ago to avoid a Dart, and heard a big crack as the bottom (ply) rudder pivot gave way. I repaired it by fitting a standard ally Seasure fitting which lasted another couple of sails but then the whole stock gave up. So that left me with three evenings to build a brand new stock before Sailfest. This time I laminated ply cheeks (used foam last time), cut the old stock off the tiller and epoxied it all back together, wrapped it in Carbon and scrambled to fit it out late the night before leaving. 2. Kicker strop 3 mins into the 1st Sailfest race, the wind build, I pulled on more kicker - another bang, the boom strop gave out ( and I'd just checked it before launching), mad 15min reach back to shore to botch it with a bit of rope and back out for the next race. 3. Major Leak Had some great racing in challenging conditions of wind an chop. Crossed the fleet on port in race three, but felt I was going backwards, and really struggled in the chop, The bow was burying into every wave throwing sheets of water through the boat, it was just so sluggish. When I got to shore I couldn't pull the boat up the slip, there was so much water inside, I've a major major leak ! Had someone look over her with me and one obvious issue is I've got the wrong O rings on the hatches. I'm not convinced this would have let so much water in but will try that, otherwise it's a more major issue. After a frantic scramble at the end, including a broken down car and several late nights we finally launched her today. I'd particularly like to thank Daryl as the motivation for this project, plus Ben, John and Luke (in NZ) for their advice, Iain for the rig, P&B for all the fittings, Butler boats (trolley) and Sail Register (cover).  First challenge this morning was to get it out of the back garden. If it hadn't gone thru the side gate it would have to have gone over the garage roof. Plenty of room ...... : ) Then I disappeared over the horizon so no sailing photos yet

Identified lots of little details to deal with. Mainsheet rubbed on boom, bridle block kept twisting oddly, more kicker needed, all rope lengths need shortening but none of these are a problem. Only real issue is the bottom of the rudder stock sits in the stern wake creating a rooster tail of drag. Needs some major mods there. Hope for more wind than forecast tomorrow for a longer sail Yes ! It's a tight fit but the board goes through the slot ! Still loads to do, but that's the last major hurdle I was worried about, so it looks like we're on for a launch Sat morning : )

Goodness there are so many details to finish off : Completing the stock, working out an uphaul / downhaul system, progrip, griptape, footloops, splicing, mounts for cleats, epoxy/sand, epoxy/sand on the foils etc But as long as I can get the centreboard down thru the slot it'll sail next weekend whether the foils are smo

Target Launch day two weeks.

After another day of continuous sanding, I took the opportunity of the warm weather to try painting again. This time I did it outside where there's more space. I warmed the paint beforehand and rolled and tipped it on. Let's hope there's not too many runs, sags and flies in the morning this time I'd planned to rout a groove and lay a strip of unidirectional carbon down the centreboard, but wimped out and just sheathed them in 200g cloth. Hope it's strong enough !

Spent most of the weekend on a variety of bits and pieces.Cleared the building base out and passed them on to the next Farr builder Dan, which created a bit of space. Lot's of sanding - my hands are so sore !Finished the centreboard blank then got stuck straight into the rudder and finished it too. Both ready for sheathing. More sanding on the decks and another coat of varnish. i'm still not satisfied with them, but I gota take it sailing soon so I think they'll have to do!

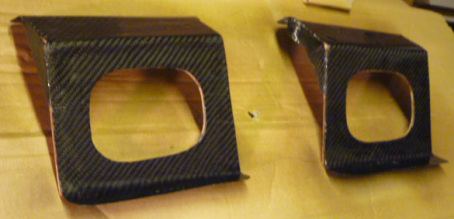

I also built a couple of ply boxes and carboned them to mount the control line cleats |

Archives

November 2016

Categories

All

|

||||||||||||

| Dave's Farr 3.7 project |

|

RSS Feed

RSS Feed